Today in the competitive manufacturing sector, companies are increasingly resorting to production line automation with a view to ensuring efficiency while also cutting down costs and enhancing productivity. In production line automation, sophisticated machinery, robots and control systems are used to automate different manufacturing processes.

Enhanced efficacy is one of the key advantages of production line automation. By automating repetitive and labour-intensive activities e.g., assembling, packaging and quality control automation reduces downtime in production and speeds cycle times. This results not only into increased output but also enhances consistency and quality leading to improved customer satisfaction.

The adoption of many producers is likely going to rise because businesses seek better ways for optimising their manufacturing processes and becoming competitive globally in a market where everyone is looking for efficiency gains that leads them towards leaner supply chains.. Companies stand to gain from streamlining their operations through investing into automation technologies thus increasing their efficiencies positioning themselves for long-run success given that world is gradually being automated.

Production speed: 150/min-180/min

Bag width: 320-580 mm

Bottom width: 90-200 mm

Internal reinforcement length: 100-500 mm

Finished product length: 360-900 mm

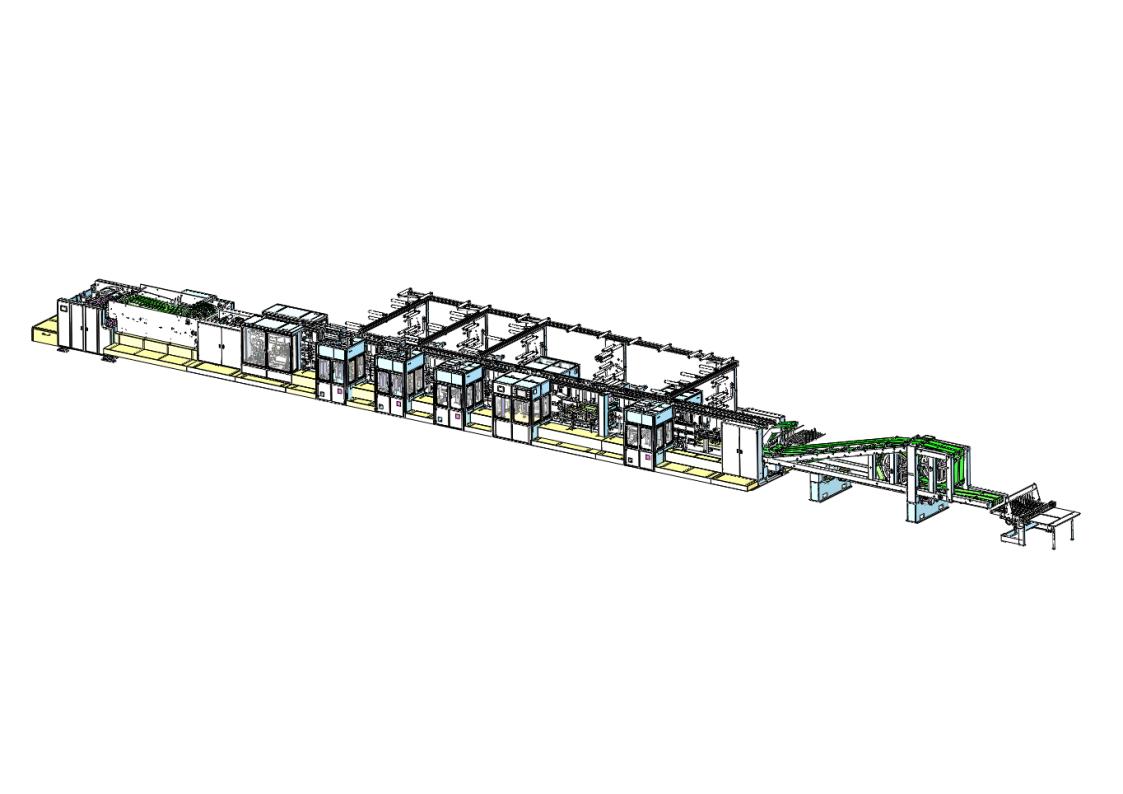

| Food valve mouth paper bag intelligent bottom paste machine | |||

| Basic Information | |||

| model | BM2022-2F-2B-2D | Unit product size | 32*4.8*2.3M |

| Voltage | 380V | weight | 37.6 tons |

| Energy consumption | low energy consumption | Transport Packaging | container |

| manufacture | Jiangmen, China | production bag | 2-4 paper+1PE film, paper-plastic composite |

| production capacity | 130-150 strips/min | Finished length | 360-900 (mm) controllable error ± 1mm |

| continuous rolling | yes | Finished width | 320-580 (mm) controllable error ± 1mm |

| layer | many | bottom width | 90-200 (mm) controllable error ± 3mm |

| intelligent | yes | Port length | 100-250 (mm) |

| Bottom paste machine equipment configuration: | |||

| High-speed rotary vacuum suction pick-up → step-by-step arrangement (with abnormality rejection function) → center distance straight embossing, 45° oblique embossing (with piercing mechanism) → straight bag ear incision → suction open horns to unfold and smooth → second First valve port insertion → second valve port insertion → internal reinforcement insertion → bottom embossing, bottom closing glue application → bottom closing forming → external reinforcement insertion → bottom turning compaction (with exception rejection) → small S compacting mechanism → count stack output | |||

Production line automation has many advantages that contribute to improved efficiency, productivity and competition in manufacturing:

Automated operations decrease dependence on manual work thereby minimizing human errors and speeding up production process with increased precision. Automation reduces labor costs, minimizes the need for overtime pay, and lowers expenses associated with errors, defects, and waste. Normally many hours or even days can be taken to do a task manually but can take only several minutes or even seconds with machine automation.

The continuous operation means that machines are running 24/7 without stopping for breaks or rest periods which leads to higher output levels as well as increased overall productivity. This continuous operation maximizes machine uptime and optimizes resource utilization.

Automation ensures uniform product quality by performing tasks precisely over and over again thus reducing variability in product quality and leading to higher customer satisfaction through less defects and reduced cases of waste generation.

Even though setting up the initial automation may cost significantly high amounts of money, it leads to substantial long-term savings in terms of costs. The greater risk refers to employment losses due to reduction in demand for labor resulting from rising wages brought about by automation.

These automated lines are designed such that they can easily be reconfigured so as to adapt to changes in production needs like new configurations, products sizes or models etcetera which allows manufacturers respond fast to alterations in consumer preferences and market demands.

There are advanced safety features including sensors and guards besides taking out workers from risky or monotonous activities hence reducing the danger of accidents at workplace while enhancing general safety standards within manufacturing industry.

Automated production lines produce large volumes of data that can be collected, analysed effectively so as to optimize processes, identify areas where improvements need to be made, inform data-based decision making among other things related with managing change within an organization’s context such as innovation strategy development based on a lean manufacturing principles approach rather than an evolutionary perspective on technological change as well as being more responsive towards ever changing consumer preferences instead of putting most emphasis on spending for promotion efforts only which may not yield any returns over time given that consumers now require real value added products not just marketing gimmicks offered by companies to boost their competitive edge in a market place dominated by few large firms having similar price points.

This competitive advantage allows them to better meet customer demands, penetrate new markets, and stay ahead of competitors. For instance, if labor is cheap and skilled it is very likely that jobs will be outsourced but if this is not the case then these positions must be kept domestically due t some other factors such as quality control issues or proximity to customers among many others.

Tasks that can be automated on a production line include material handling, assembly, welding, painting, inspection, packaging, labeling, and palletizing, among others.

Production line automation improves efficiency by reducing reliance on manual labor, minimizing errors, increasing production speed, optimizing resource utilization, and enabling continuous operation.

While production line automation is commonly used in industries such as automotive, electronics, food and beverage, pharmaceuticals, and consumer goods, its suitability depends on factors such as production volume, product complexity, and cost considerations.

Challenges of implementing production line automation may include high initial investment costs, integration with existing systems, employee training, maintenance requirements, and cybersecurity concerns.

Companies can justify the investment in production line automation by conducting a cost-benefit analysis that considers factors such as labor savings, increased productivity, improved product quality, reduced downtime, and competitive advantage.

Yes, production line automation is scalable and can be customized to accommodate changes in production requirements, such as volume fluctuations, product variations, and process improvements.