Take a look at our state of the art Paper Pouch Packing Machine, which is a game changer for companies that want to improve packaging efficiency and accuracy. The machine is designed for speed and accuracy in handling various packing needs.

Among its special features is the user-friendly interface of our Paper Pouch Packing Machine, which enables even those with little technical knowledge to use it. It has intuitive controls that are easy to adjust as well as a clear display screen for monitoring to guarantee optimum performance every time. In addition, its heavy duty construction plus premium quality materials translate into long term usability even during constant operation.

It can handle different sizes and types of paper pouches hence making it suitable for many applications. Our Paper Pouch Packing Machine is an effective solution whether you are into food processing, pharmaceuticals or consumer goods.

With this device in place you will enjoy increased productivity, reduced errors, and consistent quality through enhanced packaging processes by using the Paper Pouch Packing Machine we have on offer. Get more details on how this innovative machinery can revolutionize your packing system by giving us a call today thus making your company stand out among others that use outdated packaging systems. You cannot afford not having our cutting-edge packaging technology in your operations anymore!

Valve Bag Packing Machine | |||

| Basic Information | |||

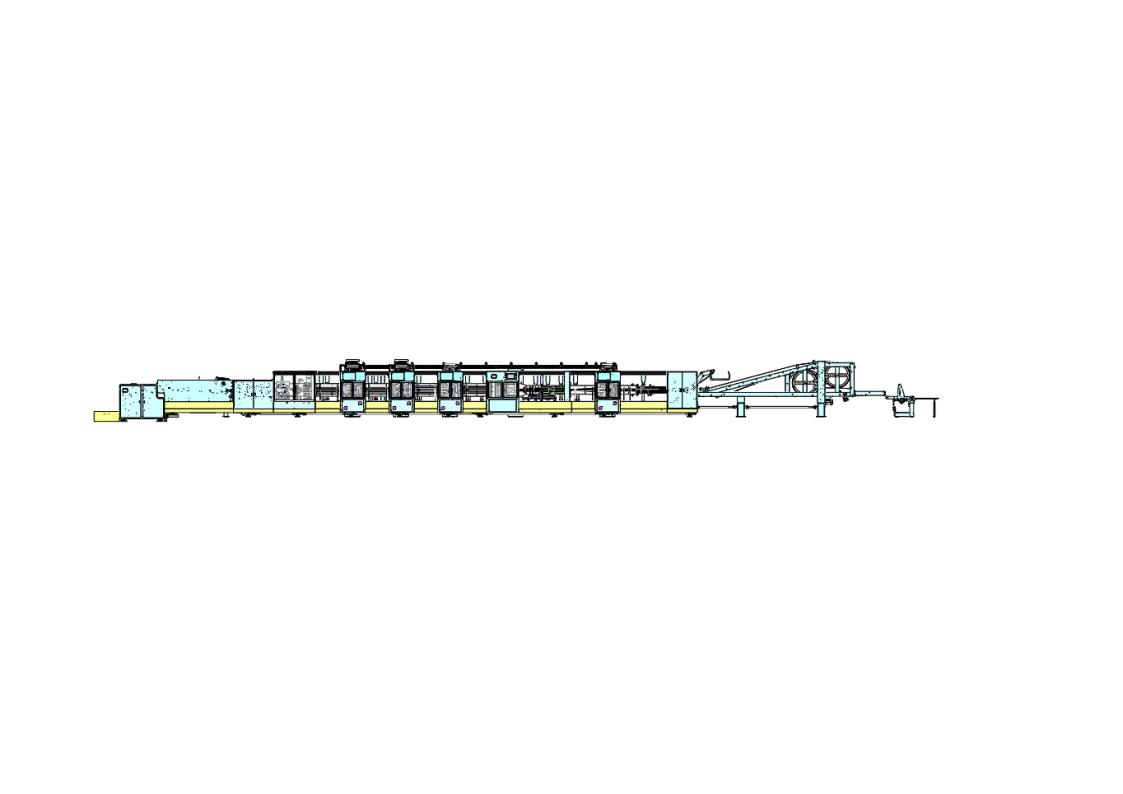

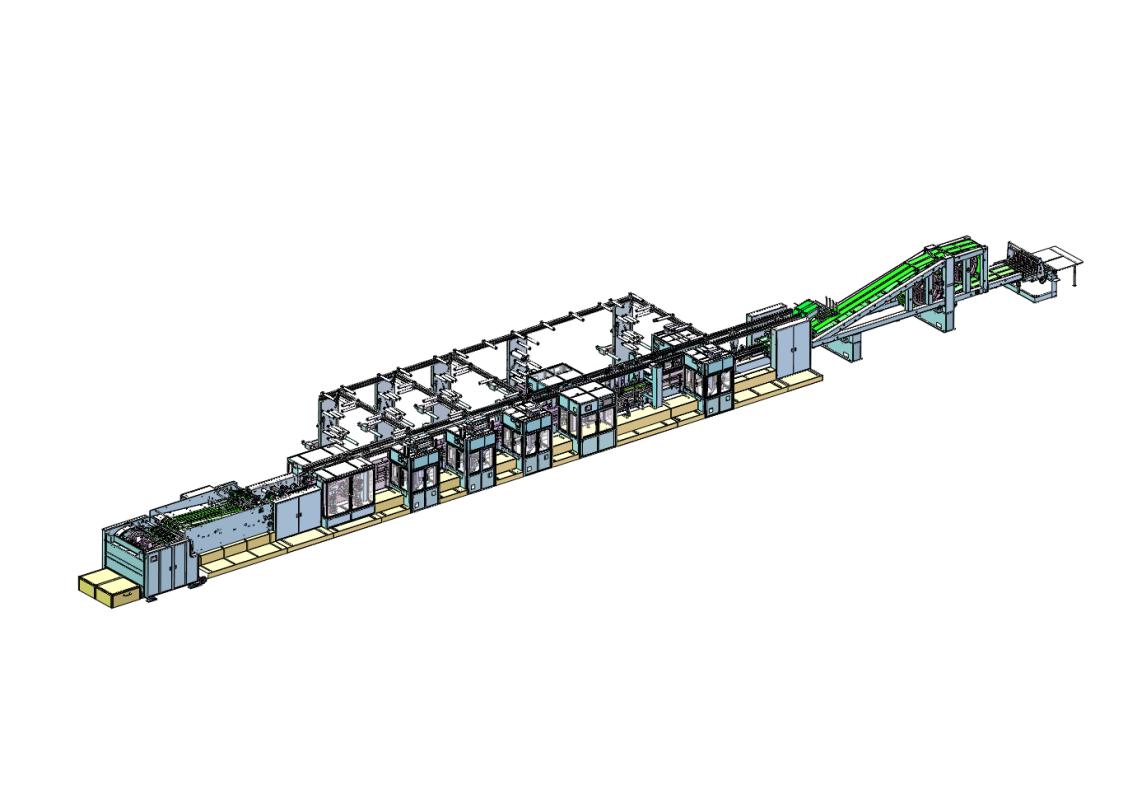

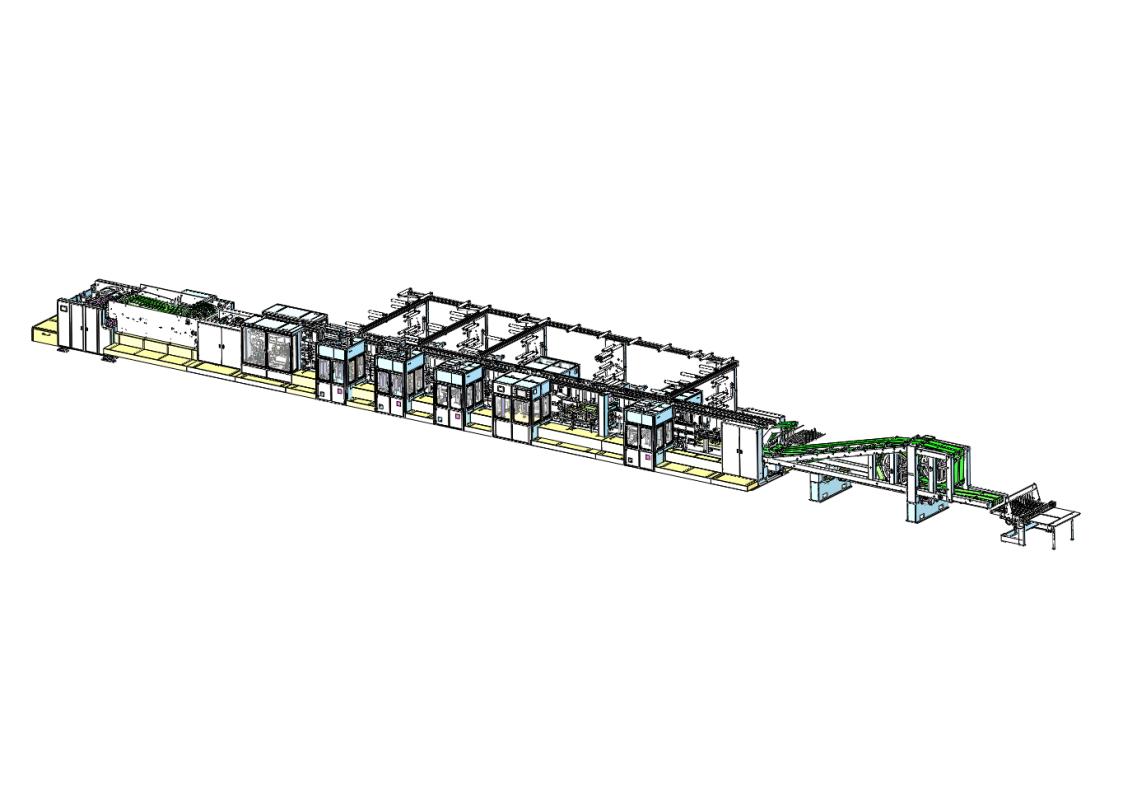

| model | BM2022-2F-2B-2D | Unit product size | 32*4.8*2.3M |

| Voltage | 380V | weight | 37.6 tons |

| Energy consumption | low energy consumption | Transport Packaging | container |

| manufacture | Jiangmen, China | production bag | 2-4 paper+1PE film, paper-plastic composite |

| production capacity | 130-150 strips/min | Finished length | 360-900 (mm) controllable error ± 1mm |

| continuous rolling | yes | Finished width | 320-580 (mm) controllable error ± 1mm |

| layer | many | bottom width | 90-200 (mm) controllable error ± 3mm |

| intelligent | yes | Port length | 100-250 (mm) |

| Bottom paste machine equipment configuration: | |||

| High-speed rotary vacuum suction pick-up → step-by-step arrangement (with abnormality rejection function) → center distance straight embossing, 45° oblique embossing (with piercing mechanism) → straight bag ear incision → suction open horns to unfold and smooth → second First valve port insertion → second valve port insertion → internal reinforcement insertion → bottom embossing, bottom closing glue application → bottom closing forming → external reinforcement insertion → bottom turning compaction (with exception rejection) → small S compacting mechanism → count stack output | |||

Bag Manufacturing:

The primary application of this intelligent machine is in the manufacturing of mortar Valve Mouth Paper Bags. It excels in the precise application of adhesive on the bag bottoms, ensuring a secure and reliable seal.

Construction Industry:

Mortar valve mouth paper bags are commonly used in the construction industry for packaging materials like cement, mortar, and other building essentials. The Intelligent Bottom Paste Machine is tailored to meet the specific needs of this sector, enhancing the packaging process.

Packaging for Powders:

With its mortar valve mouth design, the machine is ideal for packaging various powdered substances. This includes not only construction materials but also products in industries such as agriculture and chemicals.

Precision and Consistency:

The machine offers unparalleled precision in applying adhesive to the bag bottoms. This ensures a consistent and uniform seal, minimizing the risk of leaks or ruptures during transportation and storage.

Increased Efficiency:

Automation is a key advantage of the vffs packaging machine. It significantly speeds up the production process, leading to higher output and reduced manual labor requirements.

Cost-Effective:

By streamlining the manufacturing process and reducing the likelihood of defects, the machine contributes to overall cost-effectiveness. It enhances operational efficiency, leading to savings in time and resources.

Versatility:

The machine is designed to accommodate various bag sizes and specifications. Its versatility allows manufacturers to adapt to different product requirements without the need for extensive adjustments or reconfigurations.

Intelligent Control System:

The plastic cup sealing machine is equipped with an intelligent control system that ensures precise and programmable application of adhesive. This feature allows operators to customize the settings based on specific bag dimensions and requirements.

High-Speed Operation:

With its automated functionality, the machine operates at high speeds, optimizing the production line and meeting the demands of large-scale manufacturing.

User-Friendly Interface:

The interface is designed for user convenience, providing a straightforward and user-friendly experience. Operators can easily monitor and control the machine's functions through the intuitive interface.

What sets Intelligent Bottom Paste Machines apart in the packaging industry?

Mortar Valve Mouth Paper Bag Intelligent Bottom Paste Machine are cutting-edge devices designed to automate the bottom pasting process of Mortar Valve Mouth Paper Bags. Their key features include precision in pasting, automation for increased efficiency, adaptability for various bag sizes, and integrated quality control and monitoring systems. These machines represent a significant advancement in packaging technology, enhancing both production speed and the overall quality of the packaging process.

How do Paper Pouch Packing Machine contribute to production efficiency?

Intelligent Bottom Paste Machines contribute to production efficiency by automating the traditionally manual process of pasting the bottom of paper bags. This automation reduces labor costs, minimizes errors, and ensures a consistent and precise application of adhesive. The result is an increase in overall production speed and a more streamlined manufacturing process.

What are the advantages of precision in bottom pasting provided by Paper Pouch Packing Machine?

The precision in bottom pasting achieved by Intelligent Bottom Paste Machines ensures uniform application of adhesive, contributing to the overall strength and integrity of Mortar Valve Mouth Paper Bags. This precision minimizes the risk of product spillage and damage during transportation, enhancing the reliability of the packaging.

Can Intelligent Bottom Paste Machines be adapted for different bag sizes?

Yes, one of the notable features of Intelligent Bottom Paste Machines is their adaptability for various bag sizes. Manufacturers can adjust the settings to accommodate different specifications, providing flexibility in production to meet diverse market demands. This adaptability makes these machines suitable for applications beyond mortar, extending their utility across various industries.

How do Intelligent Bottom Paste Machines enhance quality control in the packaging process?

Intelligent Bottom Paste Machines are equipped with integrated sensors and monitoring systems that enable real-time quality control during the bottom pasting process. These systems can detect and identify deviations or inconsistencies in the pasting application, allowing for prompt adjustments. This feature ensures that the final Mortar Valve Mouth Paper Bags meet stringent quality standards, contributing to a higher overall product quality.