Because of the fast-changing nature of today’s manufacturing sector, companies are always looking for novel ways to make their operations more efficient and productive. Packaging automation machinery is one area that has undergone significant developments. These advanced systems have automated different packaging functions such as filling and sealing, labelling and palletising.

One of the main advantages of packaging automation machinery is that it makes activities flow smoothly. Through automating repetitive tasks which were done manually traditionally, organizations can be able to greatly improve throughput rates and reduce labour costs. This ensures consistency in packaging leading to enhanced quality products and increased satisfaction from clients.

Moreover, packaging automation machinery is flexible enough to accommodate changing production volumes. They are designed in modular form with programmable controls hence easy handling of different package sizes, shapes or materials used on various products. Packaging automation machinery provides a solution for diverse industrial requirements ranging from food and beverage industry, pharmaceuticals and consumer goods among others. Furthermore, there are safety improvements offered by these machines regarding their ergonomics. By doing away with unsafe jobs like lifting heavy loads or repeating movements continually, such mechanism enhances workplace safety while reducing the likelihood of accidents occurring at work places. In addition to this ergonomic features are provided which include adjustable heights as well as simple user interfaces that enhance operator comfort and efficiency.

Packaging automation machinery also delivers sustainability benefits beyond operational gains through smart sensor technology and state-of-the-art energy saving components resulting in resource conservation practices towards sustainable manufacturing processes. For example; optimizing packaging materials thereby minimizing wastage during packaging activities has reduced the carbon footprints associated with this process.

| Bag On Valve Filling Machine | |||

| Basic Information | |||

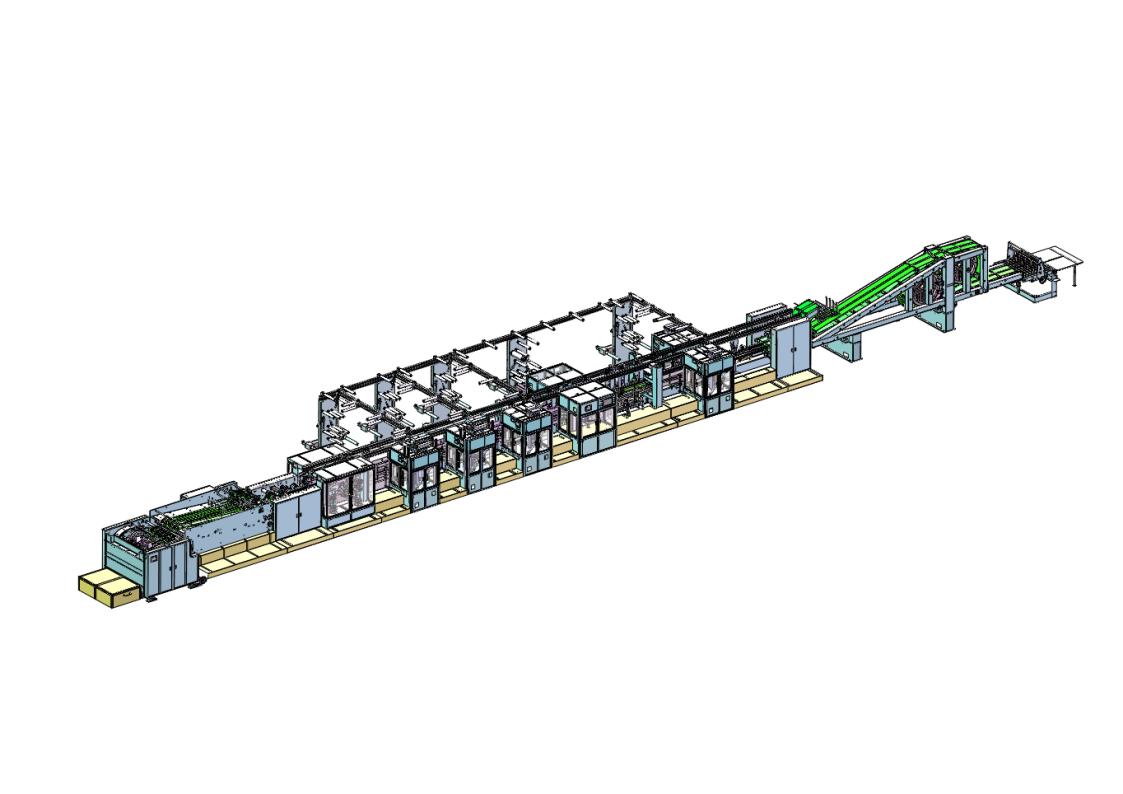

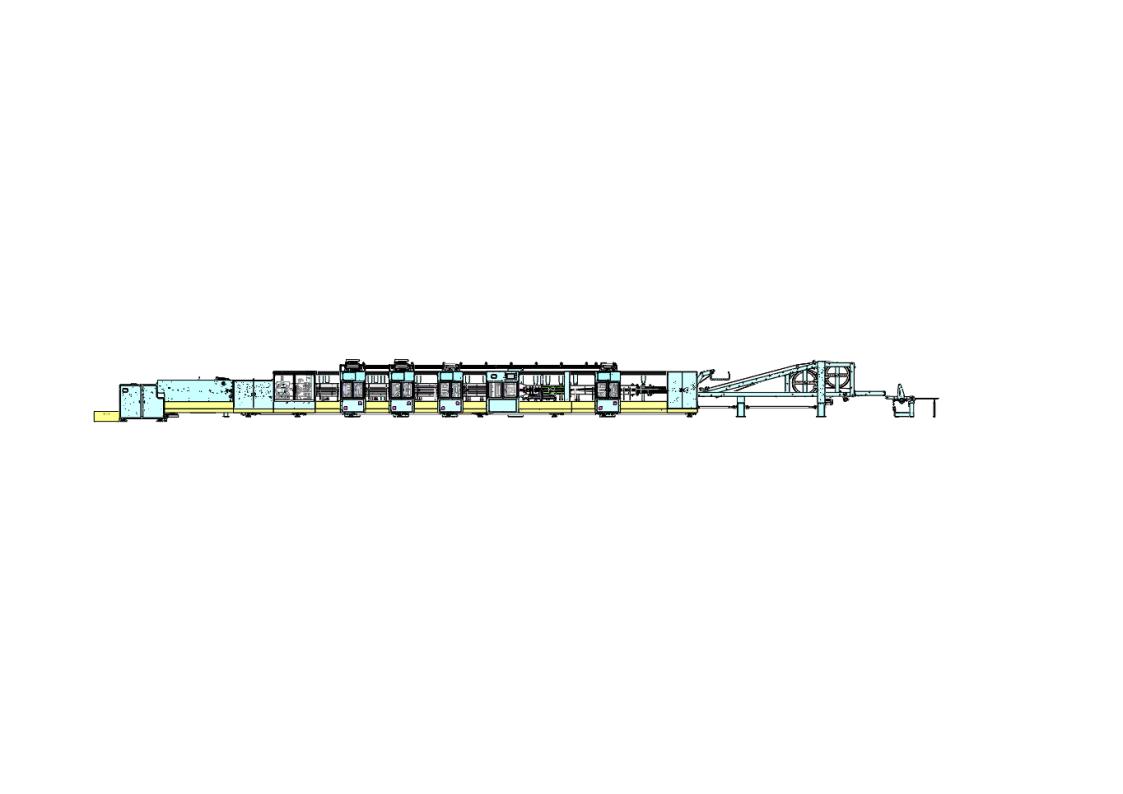

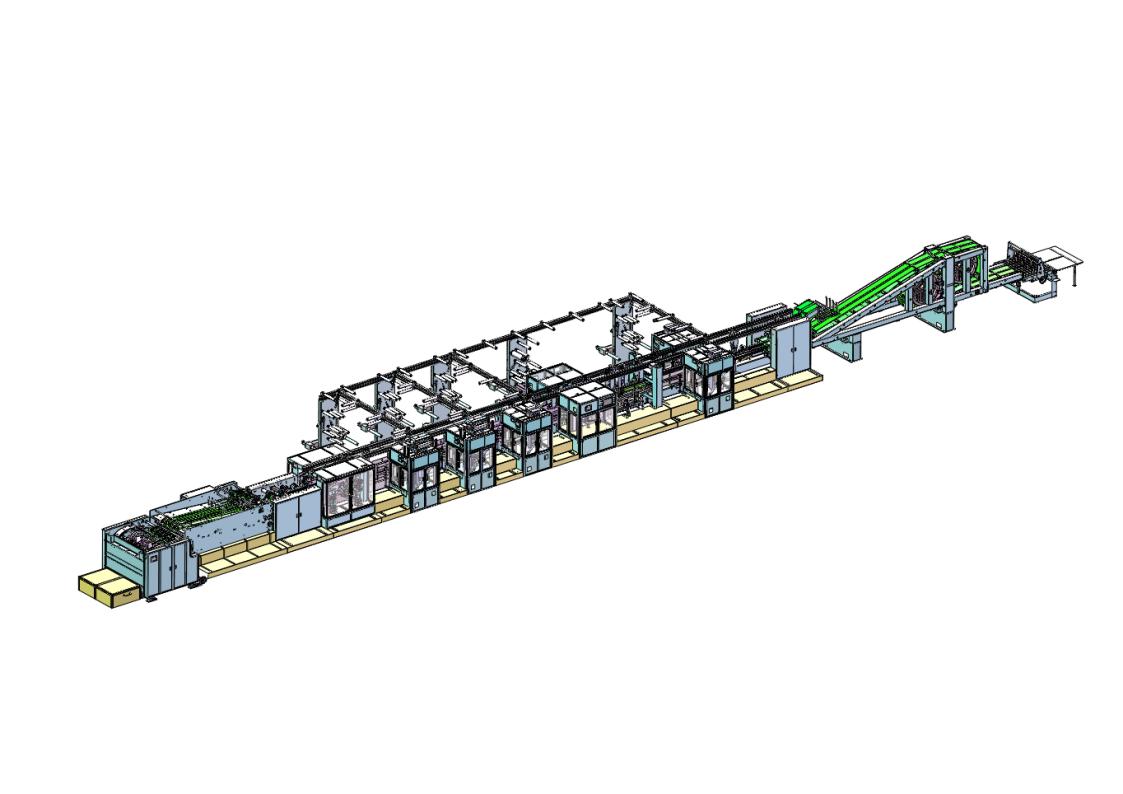

| model | BM2022-2F-2B-2D | Unit product size | 32*4.8*2.3M |

| Voltage | 380V | weight | 37.6 tons |

| Energy consumption | low energy consumption | Transport Packaging | container |

| manufacture | Jiangmen, China | production bag | 2-4 paper+1PE film, paper-plastic composite |

| production capacity | 130-150 strips/min | Finished length | 360-900 (mm) controllable error ± 1mm |

| continuous rolling | yes | Finished width | 320-580 (mm) controllable error ± 1mm |

| layer | many | bottom width | 90-200 (mm) controllable error ± 3mm |

| intelligent | yes | Port length | 100-250 (mm) |

| Bottom paste machine equipment configuration: | |||

| High-speed rotary vacuum suction pick-up → step-by-step arrangement (with abnormality rejection function) → center distance straight embossing, 45° oblique embossing (with piercing mechanism) → straight bag ear incision → suction open horns to unfold and smooth → second First valve port insertion → second valve port insertion → internal reinforcement insertion → bottom embossing, bottom closing glue application → bottom closing forming → external reinforcement insertion → bottom turning compaction (with exception rejection) → small S compacting mechanism → count stack output | |||

Automated Filling: Such machines have the capability to automate filling processes for containers or packages with products; making sure that accurate fill levels are maintained.

Sealing and Closing: Packaging automation machinery can seal containers through heat sealing, adhesive sealing, or mechanical closure systems thereby ensuring product integrity and tamper-proof packaging.

Labeling: These machines put labels on packages including product information, barcodes or any other branding components with accuracy to enhance compliance with labeling regulations and the presentation of a product.

Batch Coding and Printing: Majority of packing automation systems are usually equipped with batch coding and printing functionalities which allow date codes, batch numbers as well as variable data to be printed directly on packages.

Product Inspection: Some types of packaging automation machines have built-in inspection systems meant for checking flaws, contaminants or even discrepancies in packaging materials hence guaranteeing product quality as well as safety.

Integration with Conveyor Systems: Therefore, such machines will easily line up with conveyor systems which facilitate flow of packages along the packing line thus optimizing workflow while minimizing manual handling .

Modular Design: A modular design is an important aspect in most packaging automation systems that makes them easily customizable and scalable to accommodate different package formats, sizes or even production volumes thus making it suitable for different applications

User-Friendly Controls: These units come with easy-to-use control panels that enable operators to quickly setup, monitor and adjust various parameters during the packaging process; thus minimizing downtime while maximizing productivity at all times.

Safety Features: Packaging automation machinery includes safety devices like emergency stop buttons among others meant to ensure operator’s safety by following industry standards on occupational health and safety (OHS)

Remote Monitoring and Diagnostics: Packaging automation machinery is equipped with remote monitoring and diagnosing capabilities which enhances machine performance monitoring, trouble shooting and remote maintenance hence increasing uptime while reducing maintenance costs.

Packaging automation machinery can automate a wide range of tasks, including filling containers with products, sealing packages, applying labels, printing batch codes, inspecting products for defects, and palletizing finished goods.

While packaging automation machinery is widely used across various industries such as food and beverage, pharmaceuticals, cosmetics, and consumer goods, its suitability depends on factors such as production volume, product characteristics, and packaging requirements.

Many packaging automation machinery systems feature modular designs that allow for easy customization to accommodate different packaging formats, sizes, and production volumes.

Yes, operators typically receive training on how to operate, set up, and maintain packaging automation machinery to ensure safe and efficient operation.

Regular maintenance is necessary to keep packaging automation machinery in optimal working condition. This may include cleaning, lubricating, and inspecting the equipment, as well as replacing worn parts as needed.

Yes, packaging automation machinery can be integrated with other production equipment such as conveyor systems, filling machines, and inspection systems to create a fully automated packaging line.

Factors to consider include production volume, packaging requirements, available space, budget, and the level of automation desired.

Packaging automation machinery can be purchased from manufacturers, distributors, or specialized suppliers of packaging equipment and machinery. It's important to research and compare options to find the right solution for your specific needs.