Cement Valve Mouth Paper Bag intelligent bottom paste machine

Introducing our state-of-the-art automatic pouch sealing machine, a cutting-edge innovation in the packaging industry. Specifically designed for businesses requiring a reliable and efficient solution for sealing pouches, this machine sets new standards for performance and productivity.

The automatic pouch sealing machine is an advanced paper bag production line, which can seamlessly combine the valve mouth and mouth of the cement bag. It has a cutting-edge intelligent control system that enables it to automatically control the bagging process, ensuring consistent and precise results.

The machine has a unique feature that sets it apart from its competitors - the bottom stick system. The system can automatically and efficiently apply glue to the bottom of the paper bag, ensuring that the stability and safety of the cement inside the bag are enhanced.

The low energy consumption paper bag smart bottom gluer has a humanized design and a simple and intuitive interface. With this machine, enterprises in the cement industry can enjoy many benefits, including reducing labor costs, increasing production efficiency and improving product quality. Ideal for high-volume production locations, its robust design ensures longevity and minimal maintenance requirements.

To sum up, the cement valve nozzle paper bag intelligent bottom paste machine is a subversive in the cement industry. Its innovative features, exceptional quality and superior performance make it the ultimate investment for businesses looking to optimize their bagging process and increase profitability. If you are looking for a reliable, efficient and economical solution for your bagging needs, the cement valve nozzle paper bag intelligent bottom paste machine is your best choice!

| Cement valve mouth paper bag intelligent bottom paste machine | |||

| Basic Information | |||

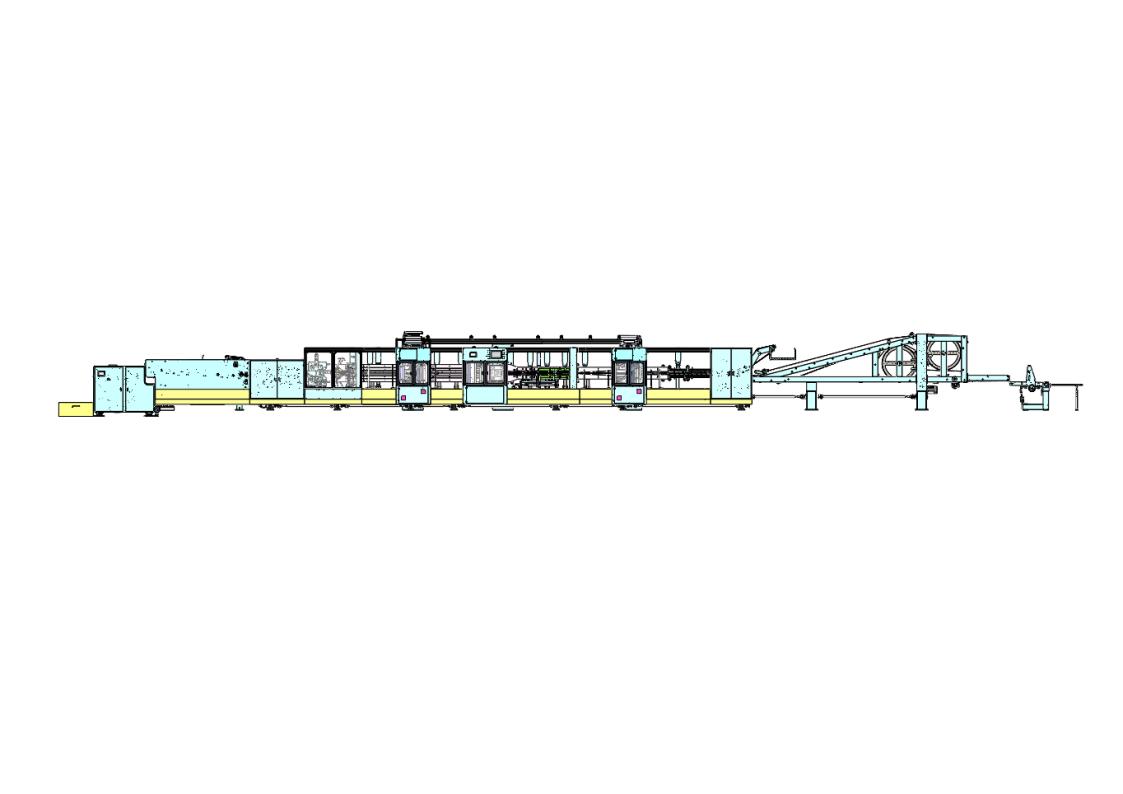

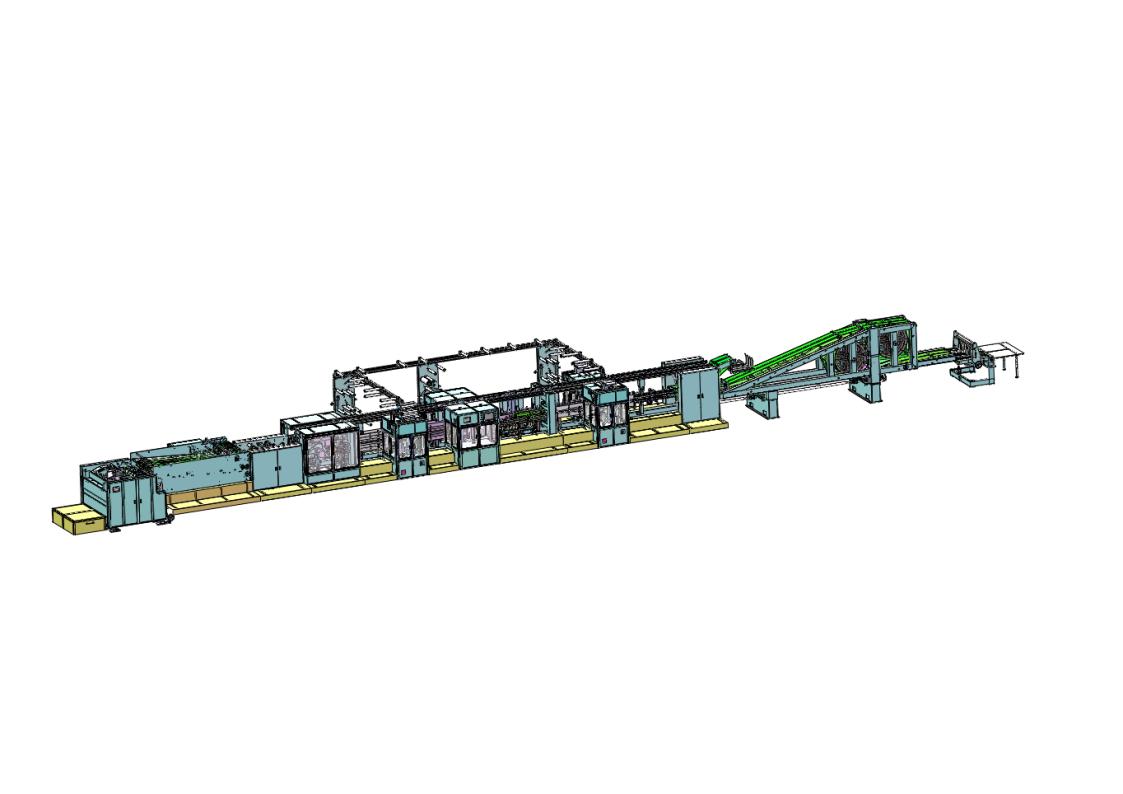

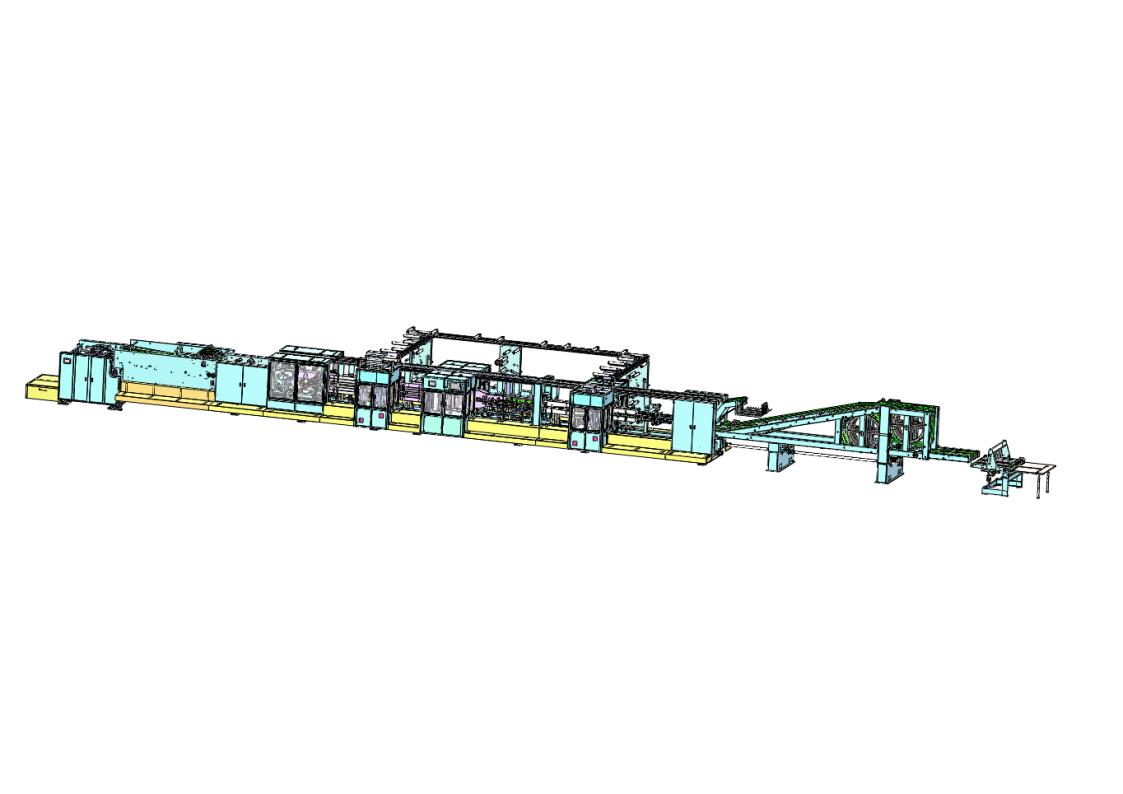

| model | BM2022-1F | Unit product size | 27.8*4.8*2.1M |

| Voltage | 380V | weight | 30 tons |

| Energy consumption | low energy consumption | Transport Packaging | container |

| manufacture | Jiangmen, China | production bag | 2-4 paper+1PE film, paper-plastic composite |

| production capacity | 130-150 strips/min | Finished length | 360-900 (mm) controllable error ± 1mm |

| continuous rolling | yes | Finished width | 320-580 (mm) controllable error ± 1mm |

| layer | many | bottom width | 90-200 (mm) controllable error ± 3mm |

| intelligent | yes | Port length | 100-250 (mm) |

| Bottom paste machine equipment configuration: | |||

| High-speed rotary vacuum suction pick-up → step arrangement (with abnormality rejection function) → center-to-center straight embossing, 45° oblique embossing (with piercing mechanism) → straight ear incision at bag opening → sucking open horns to unfold and smooth → valve Inserting at the mouth → embossing at the bottom, closing the bottom and applying glue → closing the bottom and forming → turning the bottom and compacting (with abnormal rejection) → small S compacting mechanism → counting and stacking output | |||

1. Efficiency: Automatic pouch sealing machines streamline the sealing process, significantly increasing production speed and throughput compared to manual sealing methods.

2. Precision: These machines ensure consistent and uniform sealing of pouches, minimizing errors and ensuring product integrity.

3. Versatility: Many automatic pouch sealing machines are adaptable and can handle various pouch sizes, types, and materials, offering flexibility to manufacturers.

4. Labor Savings: By automating the sealing process, these machines reduce the need for manual labor, leading to significant cost savings and increased productivity.

5. Improved Productivity: With high-speed operation and minimal downtime, automatic pouch sealing machines maximize production output, meeting demand and deadlines effectively.

6. Enhanced Product Quality: Automated sealing minimizes human errors and inconsistencies, ensuring that pouches are securely sealed, maintaining product freshness and quality.

- This combined system works by automatically feeding cement-filled paper bags into the machine, where they are sealed using heat, pressure, or other sealing methods. The intelligent bottom paste machine ensures secure sealing of the bags, preventing leakage and ensuring product integrity.

- The key features include automatic feeding and sealing of cement-filled paper bags, precise valve mouth technology for controlled dispensing of cement, and intelligent bottom paste capabilities for secure bag sealing. These machines often come with programmable controls and sensors for enhanced efficiency and consistency.

- Yes, these machines are often designed to accommodate various bag sizes and types of cement compositions. They can be adjusted or configured to meet the specific requirements of different cement packaging applications.

- The quality of sealing is ensured through precise control of the sealing process, including temperature, pressure, and sealing duration. Additionally, the intelligent bottom paste capabilities ensure secure sealing of the bags, preventing any leakage.

- Yes, manufacturers often offer options for customization to tailor the machine to the specific needs and preferences of different cement packaging operations. This may include adjustments in sealing parameters, conveyor speed, and control systems.

- Maintenance requirements typically include regular cleaning, lubrication of moving parts, inspection of sealing elements, and replacement of worn or damaged parts to ensure optimal performance and longevity of the machine.