This is introducing the Auto Bag Packaging Machine, which is the latest automated packaging solution that has been developed. This machine’s quality and efficiency have never been matched for they are produced using high technology materials. Jiangmen in China is where this item is made from as there it can be depended upon to pack a wide range of products with precision. The Auto Bag Packaging Machine we offer guarantees uniformity and high standards when dealing with food, pharmaceuticals or industrial goods.

The machine is designed for low power consumption hence energy saving and cost effective packaging solutions. It has an operating voltage of 380V and weighs 40.5 tons making it suitable for heavy-duty use. For handling safety reasons, the shipping package comes in a container.Chemical Valve Port Paper Bag intelligent bottom paste machine operates at a rate of 130-150 strips per minute thus achieving an incredible outcome. It can produce paper-plastic compound bag that contains 2-4 papers plus one PE film. The final product length varies from between 360 mm to 900mm which has an error margin +/-1mm. The width of the finished product ranges from320-580mm which also falls within ±1m tolerance level.Rolling continuously is one unique aspect about this machine that makes it have maximized efficiency levels while minimizing wastage. This further builds on its possibilities for large scale bag production that is standard across different orders.

Finally, chemical valve mouth paper bag intelligent bottomer proves to be versatile and reliable paper bag packaging machinery solution you can rely on always. Therefore, with advanced features complemented by its highly efficient design, it ensures superb results always thereby offering you great performance at good prices if you so decide to purchase them today instead….rather than remaining behind other businesses through taking a step today towards acquiring modernized equipment such as this one

| Chemical valve port paper bag intelligent bottom paste machine | |||

| Basic Information | |||

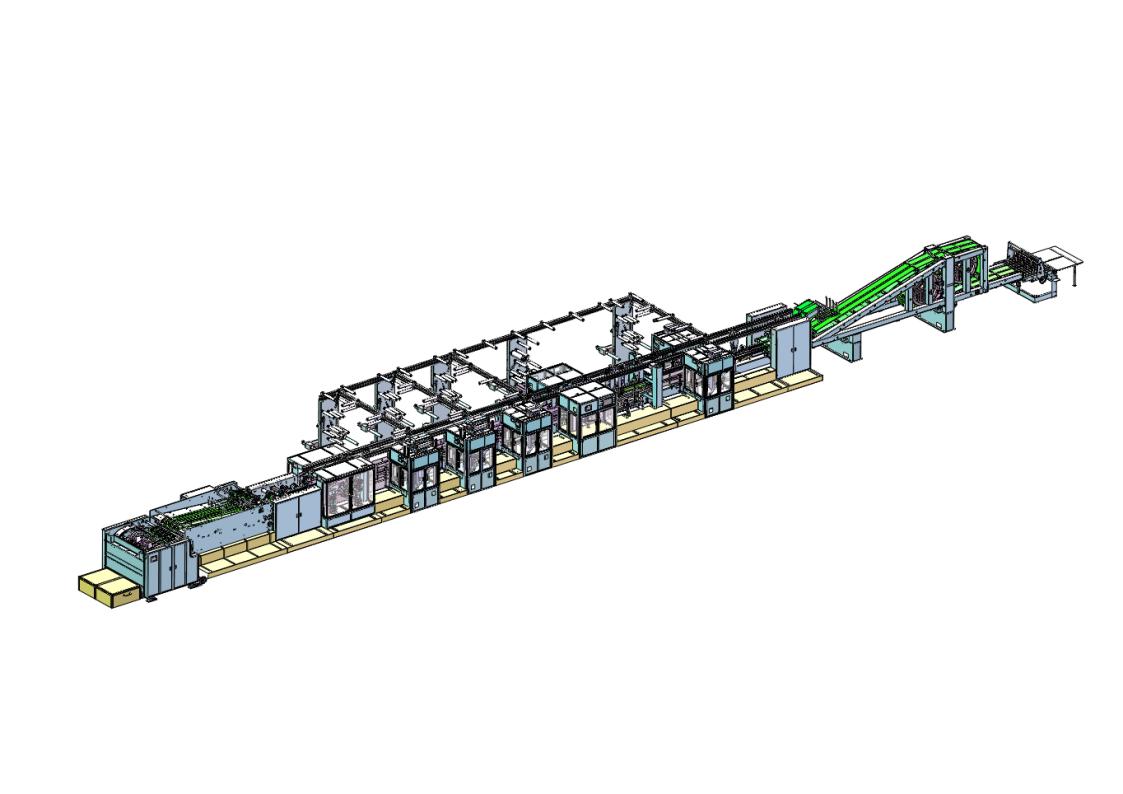

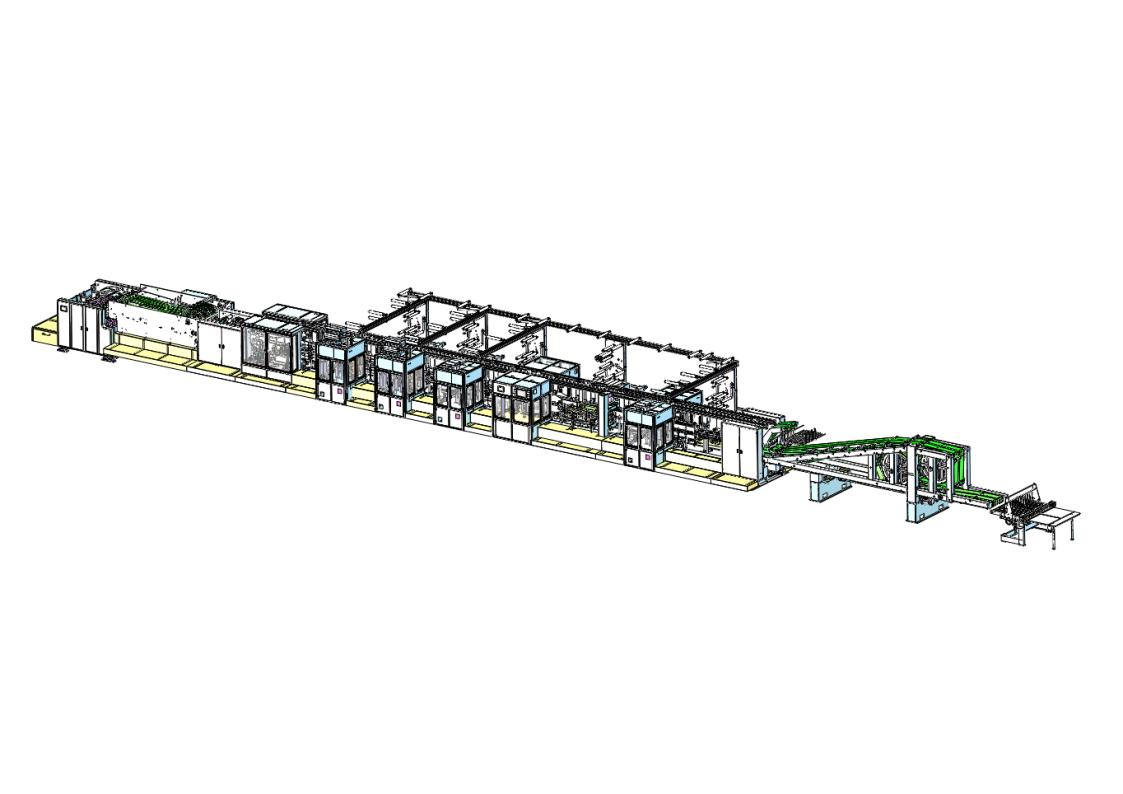

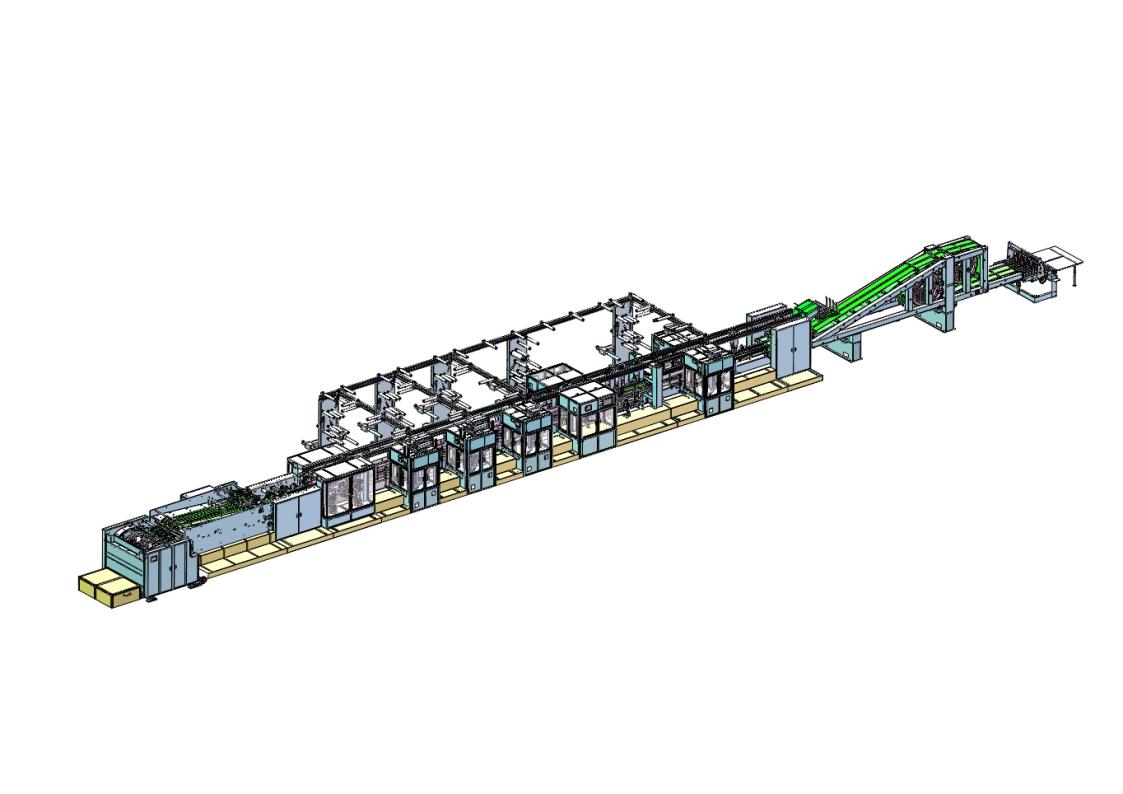

| model | BM2022-1F-1B-2D | Unit product size | 33.65*4.8*2.21M |

| Voltage | 380V | weight | 40.5 tons |

| Energy consumption | low energy consumption | Transport Packaging | container |

| manufacture | Jiangmen, China | production bag | 2-4 paper+1PE film, paper-plastic composite |

| production capacity | 130-150 strips/min | Finished length | 360-900 (mm) controllable error ± 1mm |

| continuous rolling | yes | Finished width | 320-580 (mm) controllable error ± 1mm |

| layer | many | bottom width | 90-200 (mm) controllable error ± 3mm |

| intelligent | yes | Port length | 100-250 (mm) |

| Bottom paste machine equipment configuration: | |||

| High-speed rotary vacuum suction pick-up → step arrangement (with abnormality rejection function) → center-to-center straight embossing, 45° oblique embossing (with piercing mechanism) → straight ear incision at bag opening → sucking open horns to unfold and smooth → valve Port insertion → unilateral internal reinforcement insertion at the valve port end → bottom embossing, bottom closing glue application → bottom closing forming → external reinforcement insertion → bottom turning compaction (with exception rejection) → small S compacting mechanism → counting stack output | |||

1. Precision and Accuracy

Our Chemical Valve Port Paper Bag Intelligent Bottom Paste Machine ensures precise and accurate application of paste, guaranteeing that each bag is securely sealed. This accuracy is crucial for maintaining the integrity of chemical packaging.

2. High Efficiency

Designed for rapid operation, this machine significantly increases productivity by processing large quantities of paper bags quickly. It is ideal for meeting the high demands of chemical packaging operations.

3. Durable Construction

Constructed with robust materials, the machine is built to withstand harsh industrial environments. Its durable design ensures long-lasting performance and reduces the need for frequent maintenance.

4. User-Friendly Interface

Featuring an intuitive interface, the machine is easy to operate even for personnel with minimal technical experience. The clear display and simple controls allow for straightforward adjustments and monitoring.

5. Intelligent Control System

The advanced intelligent control system optimizes the pasting process, ensuring that the bottom of each bag is uniformly and securely pasted. This results in a professional finish and enhances the packaging’s durability.

6. Versatility

Capable of handling various sizes and types of paper bags, the machine is versatile and adaptable to different chemical packaging needs. This flexibility makes it suitable for a wide range of applications within the chemical industry.

- This machine is designed to automate the packaging process of paper-plastic composite bags with valve ports, ensuring precise and efficient bottom pasting specifically for chemical products.

- The machine can produce paper-plastic composite bags that consist of 2-4 layers of paper and one PE film, making them suitable for various chemical products.

- The intelligent bottom paste feature ensures that the bottom layers of the bag are securely glued together, maintaining the bag's integrity and preventing leaks.

- The machine can produce 130 to 150 bags per minute, making it highly efficient for large-scale industrial production.

- Yes, the machine is designed for low power consumption, making it energy-efficient and cost-effective.

- Continuous rolling capability ensures a smooth and consistent production flow, reducing downtime and increasing overall efficiency.