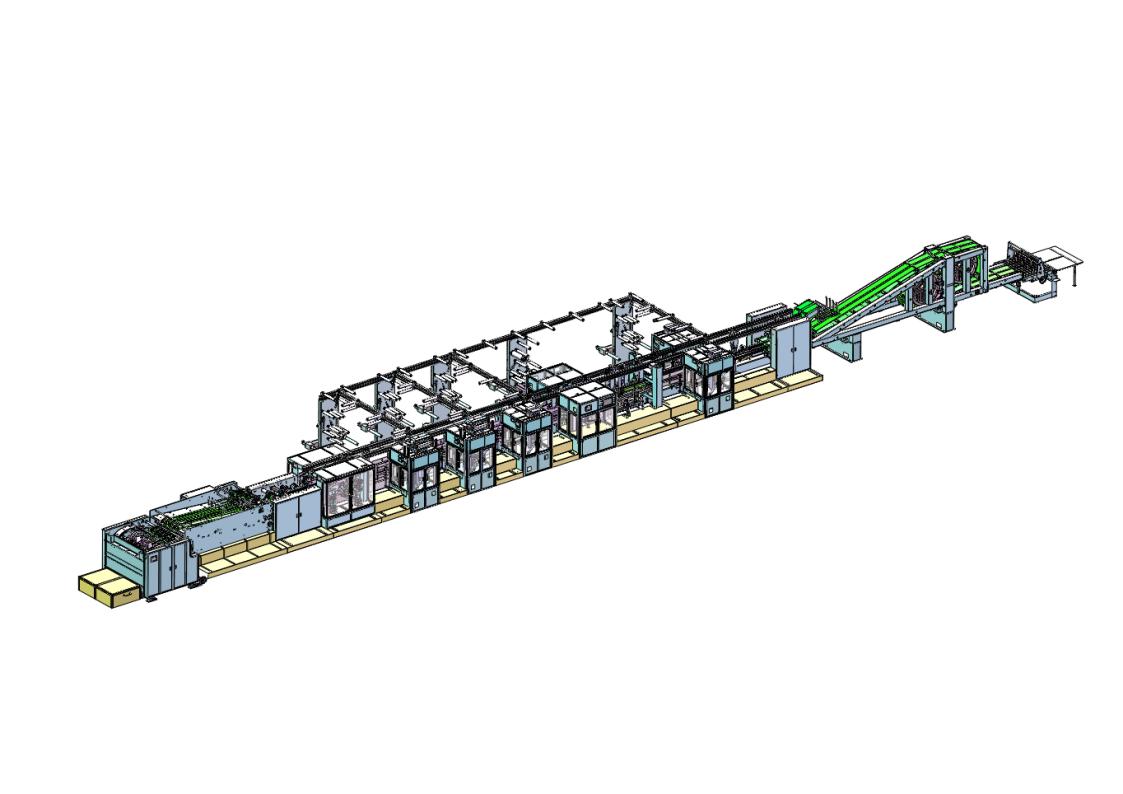

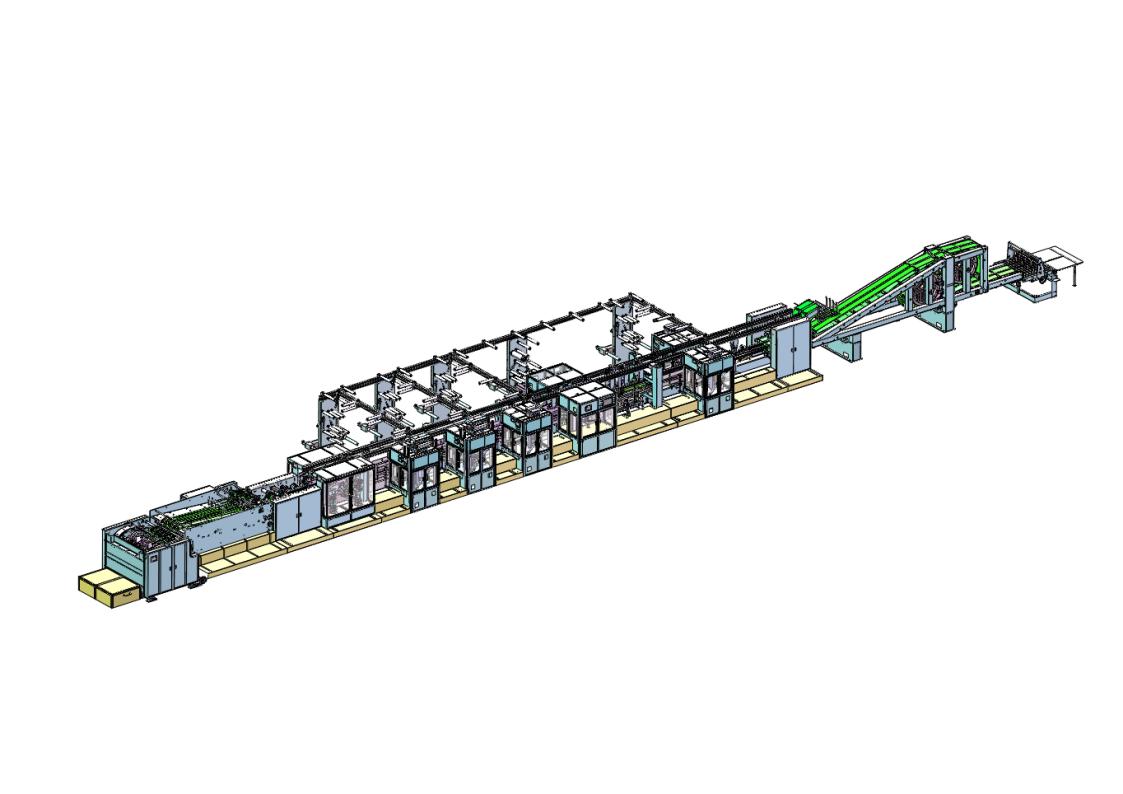

Launched the intelligent flow wrapper packaging machine for valve mouth paper bags, aiming to revolutionize the manufacture of paper-plastic composite bags. This innovative machine has advanced technology for low energy consumption and a high production capacity of up to 130-150 strips per minute.

The BM2022-2F-2B-2D model provides not only efficiency but also precision as it has a finished length and width error controllable to ±1mm. With continuous rolling capability, it is guaranteed that the machine can keep up with the demands of mass production.

Manufactured in Jiangmen, China, the size of a single product is 32*4.8*2.3M, and the total weight is 37.6 tons. It is equipped to handle 2-4 layers of paper, 1PE film for perfect paper-plastic composite bags.

But where the machine is really smart is that it can produce bags with valves for easy filling of pharmaceuticals and other materials. This feature enhances product preservation and shelf life, keeping contents fresh and safe.

Packaged in containers for easy transport, this valve-top paper bag smart primer is the perfect addition to any manufacturing plant. Embrace the future of bag production with this machine and watch efficiency and profits soar.

| Intelligent bottom paste machine for medicine valve mouth paper bag | |||

| Basic Information | |||

| model | BM2022-2F-2B-2D | Unit product size | 32*4.8*2.3M |

| Voltage | 380V | weight | 37.6 tons |

| Energy consumption | low energy consumption | Transport Packaging | container |

| manufacture | Jiangmen, China | production bag | 2-4 paper+1PE film, paper-plastic composite |

| production capacity | 130-150 strips/min | Finished length | 360-900 (mm) controllable error ± 1mm |

| continuous rolling | yes | Finished width | 320-580 (mm) controllable error ± 1mm |

| layer | many | bottom width | 90-200 (mm) controllable error ± 3mm |

| intelligent | yes | Port length | 100-250 (mm) |

| Bottom paste machine equipment configuration: | |||

| High-speed rotary vacuum suction pick-up → step-by-step arrangement (with abnormality rejection function) → center distance straight embossing, 45° oblique embossing (with piercing mechanism) → straight bag ear incision → suction open horns to unfold and smooth → second First valve port insertion → second valve port insertion → internal reinforcement insertion → bottom embossing, bottom closing glue application → bottom closing forming → external reinforcement insertion → bottom turning compaction (with exception rejection) → small S compacting mechanism → count stack output | |||

Valve Bag Compatibility: These machines are specifically designed to handle valve bags, which are bags with a pre-made valve or spout attached to the bag's opening. The valve allows for controlled filling and efficient sealing of the bag without the need for additional equipment.

Material Handling: Valve bag packing machines can handle a wide range of materials, including cement, fertilizer, chemicals, minerals, food products (such as flour, sugar, and rice), pet food, and more. The machines are equipped with mechanisms to accurately dispense and fill the bags with the desired quantity of material.

Automatic Operation: Most valve bag packing machines operate automatically, with minimal manual intervention required. They are equipped with sensors, controls, and programmable logic controllers (PLCs) that regulate the filling process, ensuring accurate weighing and consistent bagging results.

Weighing and Filling Systems: Valve bag packing machines are equipped with weighing and filling systems that measure the desired quantity of material to be dispensed into each bag. These systems can be configured to achieve precise weight accuracy according to the specified requirements.

Bag Sealing Mechanism: After the bag is filled with the material, the valve bag packing machine seals the bag's valve or spout to prevent leakage and maintain product integrity during storage, handling, and transportation. Various sealing mechanisms, such as heat sealing or stitching, may be employed depending on the bag and material characteristics.

Flexibility and Customization: Valve bag packing machines can be customized to accommodate different bag sizes, materials, and production requirements. They may feature adjustable filling speeds, bag clamps, bag handling mechanisms, and other components to meet specific application needs.

High Throughput: Valve bag packing machines are designed for high-speed operation and can fill a large number of bags per hour, making them suitable for high-volume production environments. Their efficiency and reliability contribute to increased productivity and reduced labor costs.

Quality Control and Monitoring: Advanced valve bag packing machines may incorporate quality control and monitoring features, such as weight verification, bag integrity checks, and production data logging. These capabilities help ensure consistent product quality and traceability throughout the packaging process.

- A Flow Wrapper Packaging Machine is designed to automate the packaging process, specifically for valve mouth paper bags, revolutionizing the manufacture of paper-plastic composite bags.

- The BM2022-2F-2B-2D model offers advanced technology for low energy consumption and high production capacity, producing up to 130-150 strips per minute with precision control over finished length and width errors to ±1mm.

- The machine is equipped to handle 2-4 layers of paper and 1PE film, allowing for the production of perfect paper-plastic composite bags.

- The machine can produce bags with valves, facilitating easy filling of pharmaceuticals and other materials, thereby enhancing product preservation and shelf life.

- The machine is packaged in containers for easy transport, ensuring convenience and safety during shipping and installation.

- The machine's continuous rolling capability ensures that it can keep up with the demands of mass production, maximizing output and meeting production targets.

- Precision control over finished length and width errors to ±1mm ensures the consistency and quality of the produced bags, meeting stringent manufacturing standards and customer requirements.